7 18 callister rethwisch.

Ceramic material ceramic stress strain curve.

The hard fired materials exhibit straight line deformation to failure while the softer fired have a proportional elastic limit beyond which the stress strain curve deviates from a straight line.

Cracks cannot easily propagate in tough materials making metals highly resistant to cracking under stress and gives their stress strain curve a large zone of plastic flow.

With a very short elastic region but highly capable of supporting huge stresses.

1 metals al alloy stress strain curve.

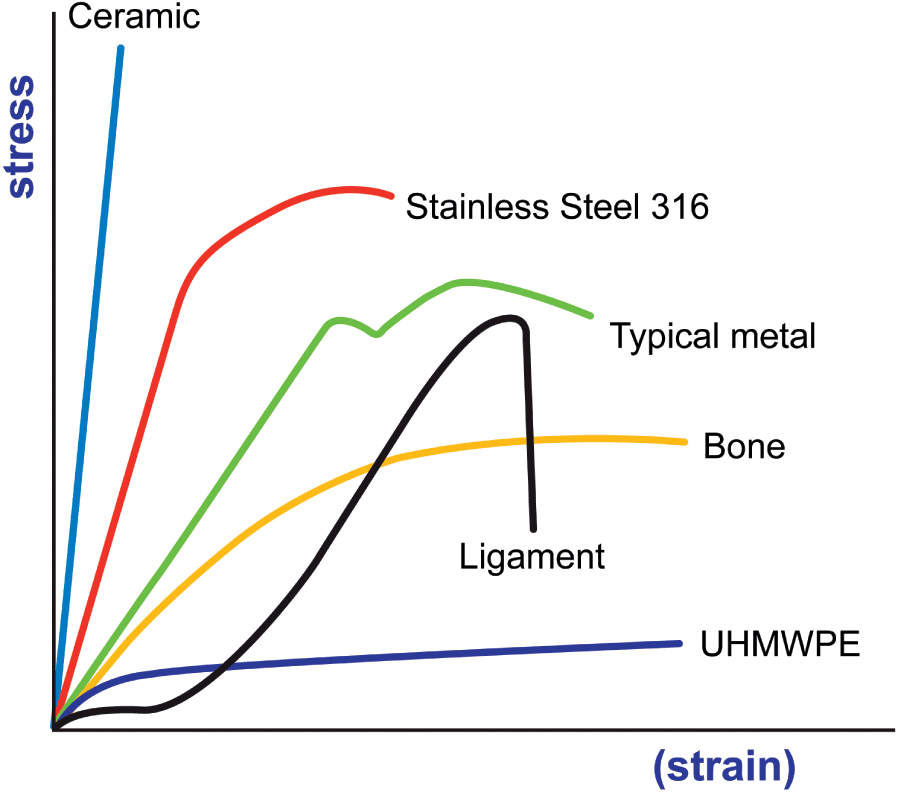

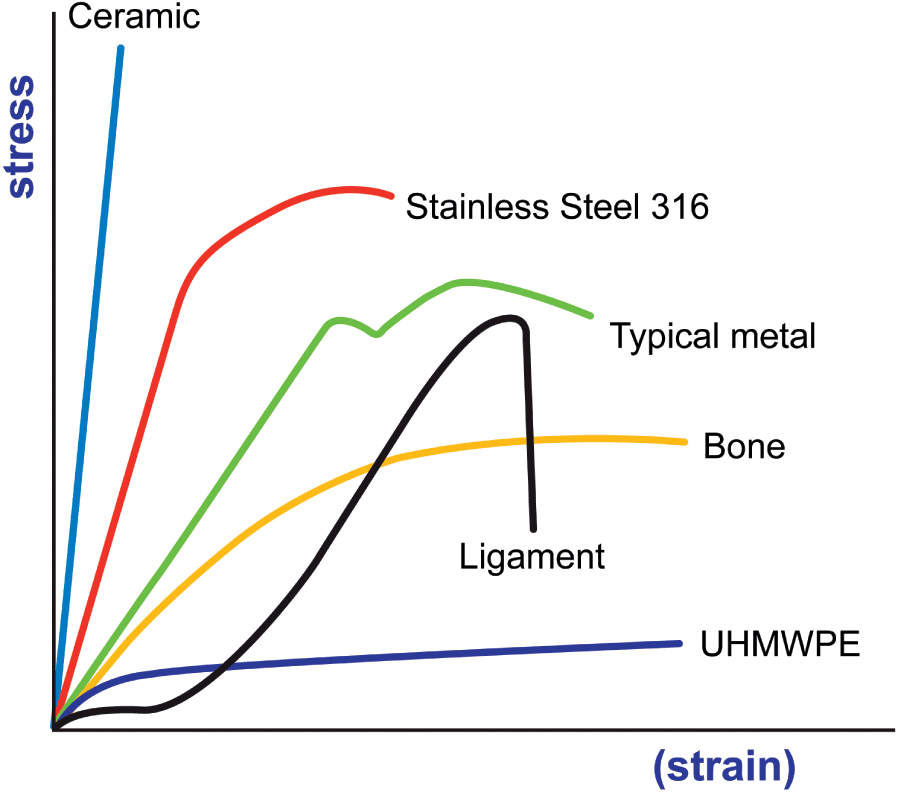

In engineering and materials science a stress strain curve for a material gives the relationship between stress and strain it is obtained by gradually applying load to a test coupon and measuring the deformation from which the stress and strain can be determined see tensile testing these curves reveal many of the properties of a material such as the young s modulus the yield strength.

Elastomers are the ones that strains more w a lower stress.

Click the resistance to fracture or area under the stress strain curve is the called the toughness.

We discussed this earlier.

The stress strain behavior of a variety of duplex ceramics was measured with the aid of strain gauges attached to the tensile surface of beams in four point flexure.

2 stress strain curve for ceramics.

Volume 29 issue 9 september 1946.

And finally analogous to ceramics are the stiff fibers and rigid plastics.

For brittle ceramics a three point bending apparatus shown in the figure below is used determine the stress strain behavior and the measurement results are used to calculate an equivalent modulus of elasticity.

The curve is linear between the origin and the first point.

If the cyclic stress strain curve lies above below the monotonic stress strain curve the material cyclically hardens softens the cyclic fatigue behavior of ceramic materials has received.

Generally a ceramic with more defects is weaker.

Received 31 october 1994.

Another way at looking at resistance to failure for ceramic materials is to examine the energy required to drive cracks through the system.

A comparison of the cyclic and monotonic stress strain curves allows one to assess the cyclically induced changes in deformation resistance.

S19 s27 1996 elsevier science ltd acta metallurgica inc.

The duplex materials consisted of a matrix of alumina and alternatively of yttria tetragonal zirconia composites without 2y tzp and with alumina 3y tzp20a.

Data indicate that engineering formulas based on elastic materials may be applied to ceramic materials.

Plot the diagram and determine the modulus of elasticity modulus of resilience and modulus of toughness.

Ceramics have a lower fracture toughness but show an exceptional improvement in the stress fracture that is attributed to their 1 5 orders of magnitude strength increase.

Printed in great britain 0956 7151 95 00204 9 indentation stress strain curves for quasi ductile ceramics a.

Data taken from a stress strain test for a ceramic are given in the table.